Blowout preventer manufacturers play a crucial role in the oil and gas industry. These manufacturers produce essential safety equipment designed to control and seal oil and gas wells, preventing catastrophic blowouts. A blowout preventer (BOP) is a critical device that ensures the safety of drilling operations by mitigating the risk of uncontrolled fluid release from the well.

Importance of Blowout Preventers

The significance of blowout preventers cannot be overstated. Blowout preventer manufacturers design these devices to withstand extreme pressure and harsh environmental conditions. By providing a robust line of defense against blowouts, these manufacturers help protect lives, the environment, and assets. The catastrophic consequences of blowouts, such as the Deepwater Horizon incident, underscore the need for reliable BOPs.

Key Players in the Market

Several leading blowout preventer manufacturers dominate the market, providing innovative solutions to the oil and gas industry. Companies like Cameron, NOV (National Oilwell Varco), and Schlumberger are renowned for their high-quality BOPs. These manufacturers invest heavily in research and development to continuously improve the safety and efficiency of their products.

Types of Blowout Preventers

Blowout preventers come in various types, each suited to specific applications and well conditions. The main types include:

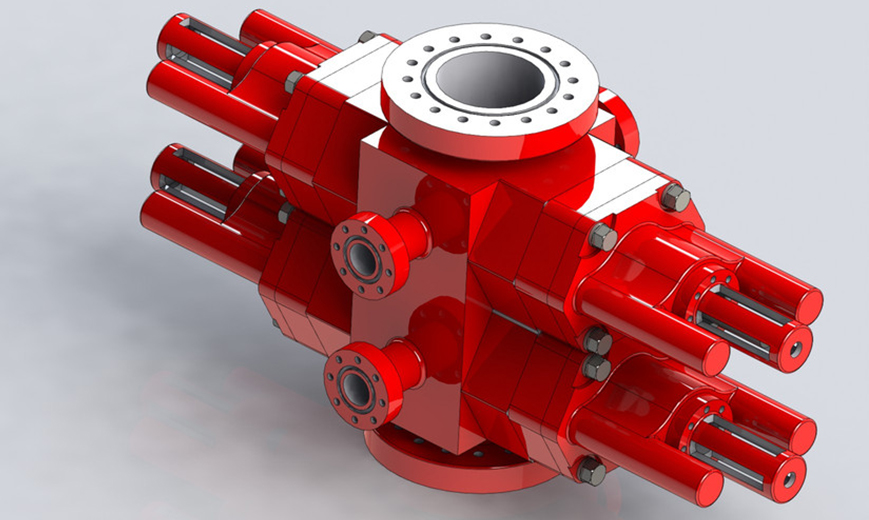

Ram Blowout Preventers

Ram BOPs use rams, which are steel blocks, to seal the wellbore. Blowout preventer manufacturers offer different ram types, such as pipe rams, blind rams, and shear rams, each serving a unique purpose in well control.

Annular Blowout Preventers

Annular BOPs use a rubber sealing element to close around the drill pipe, casing, or even open hole. This type of BOP is versatile and can seal irregular shapes, making it a valuable tool in well control.

Subsea Blowout Preventers

Subsea BOPs are designed for deepwater drilling operations. These blowout preventers are installed on the seabed and must withstand extreme pressures and harsh conditions. Leading blowout preventer manufacturers produce highly reliable subsea BOP systems to ensure the safety of offshore drilling operations.

Innovations and Advancements

Blowout preventer manufacturers continuously strive to enhance the performance and reliability of their products. Recent innovations include:

Advanced Materials

Manufacturers are using advanced materials, such as high-strength alloys and elastomers, to improve the durability and performance of BOPs.

Digital Monitoring

The integration of digital monitoring systems allows for real-time data collection and analysis, enabling proactive maintenance and early detection of potential issues.

Improved Shear Technology

Innovations in shear ram technology have increased the cutting capabilities of BOPs, ensuring they can sever even the toughest drilling pipes in emergency situations.

Conclusion

Blowout preventer manufacturers are essential to the safety and efficiency of the oil and gas industry. Their continuous efforts to innovate and improve BOP technology help prevent catastrophic blowouts, protecting lives, the environment, and valuable resources. As the industry advances, the role of these manufacturers remains pivotal in ensuring safe and sustainable drilling operations.