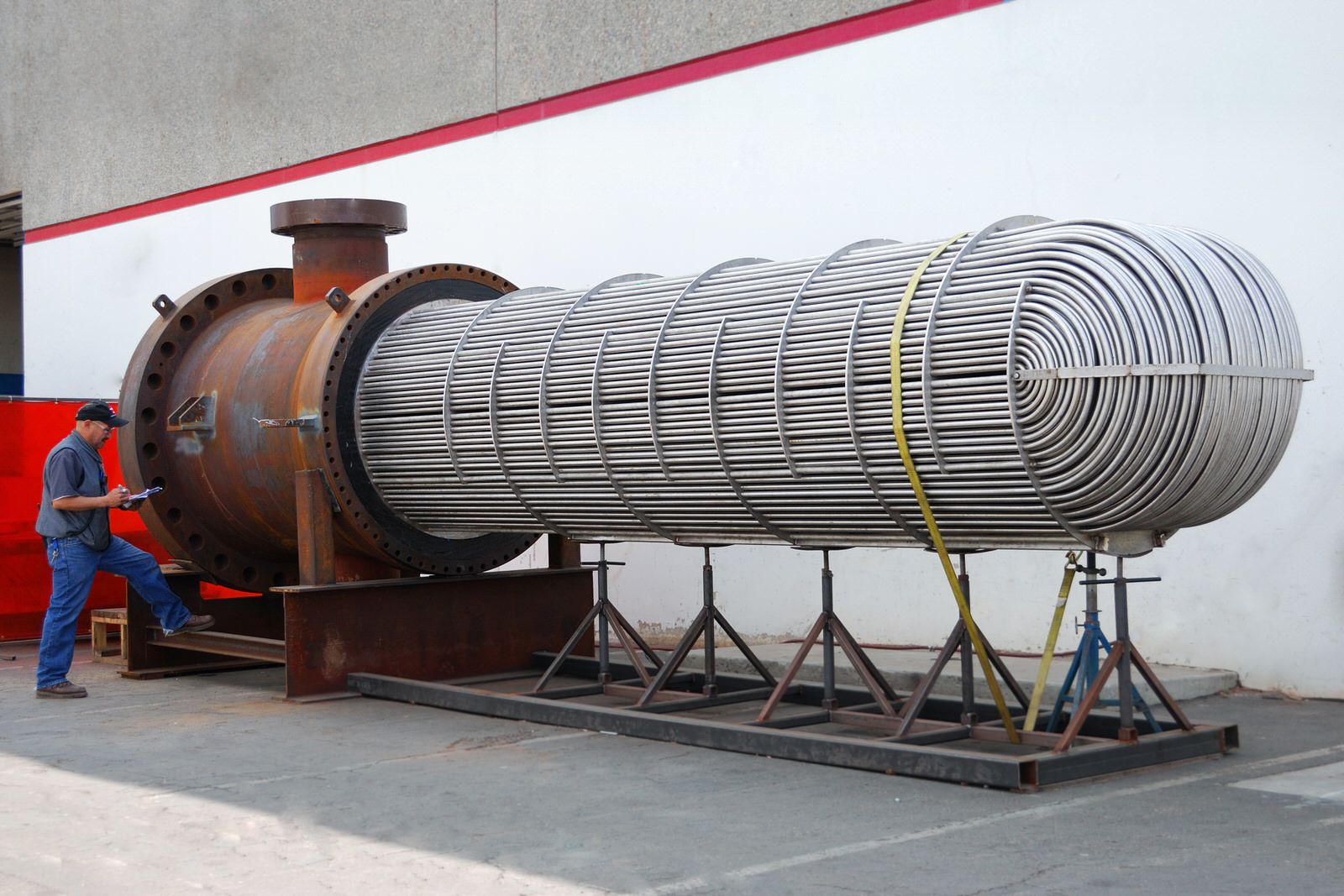

Shell and tube heat exchangers are pivotal components in numerous industries, facilitating the transfer of heat between fluids with precision and efficiency. The manufacturing process of these devices involves several key steps, each critical to their performance and reliability.

Innovative Design and Engineering

Designing a shell and tube heat exchanger requires meticulous attention to detail and adherence to strict engineering principles. Engineers utilize advanced software and simulation tools to create designs that optimize heat transfer while considering factors such as fluid flow rates, temperatures, pressures, and material compatibility.

Precise Fabrication Techniques

Fabricating shell and tube heat exchangers involves a series of precise techniques, including cutting, forming, welding, and assembly. Skilled welders employ specialized methods such as TIG and MIG welding to join components, ensuring the structural integrity and efficiency of the heat exchanger.

Stringent Quality Assurance Measures

Shell and tube heat exchanger and pressure vessel manufacturing adhere to stringent quality assurance standards, including TEMA Tubular Exchanger Manufacturer Association. These standards dictate requirements for design, materials, fabrication, and testing, guaranteeing that the heat exchangers meet the highest standards of safety and reliability.

Diverse Applications and Significance

Shell and tube heat exchangers find application in a wide array of industries, including oil refineries, chemical plants, and power generation facilities. They play a crucial role in maintaining the efficiency and safety of industrial processes by facilitating the transfer of heat between fluids.

Conclusion

The manufacturing of shell and tube heat exchangers is a complex and intricate process that demands expertise and precision. By adhering to strict quality standards and employing advanced fabrication techniques, manufacturers can produce heat exchangers that meet the demanding requirements of various industries. These devices are instrumental in enhancing the efficiency and safety of industrial processes, underscoring their significance in modern industrial operations.